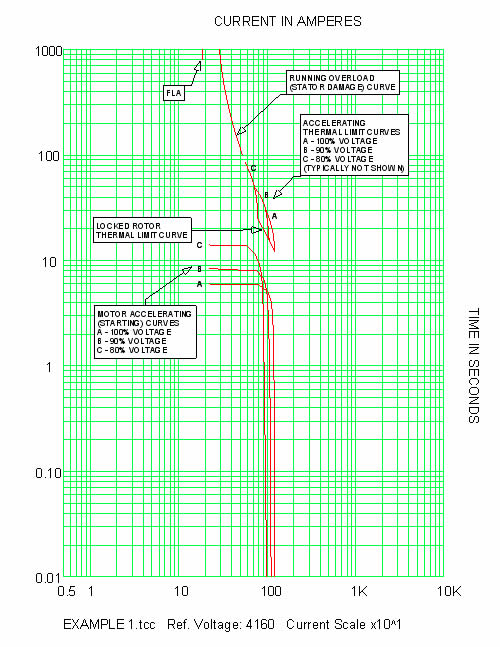

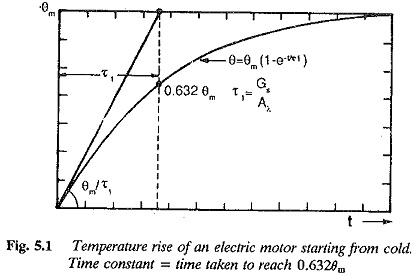

However the heating time constant of an electric motor is actually the set time for the electric motor to heat up to 63 2 percentage or 0 632 of its final temperature.

Electric motor thermal capacity.

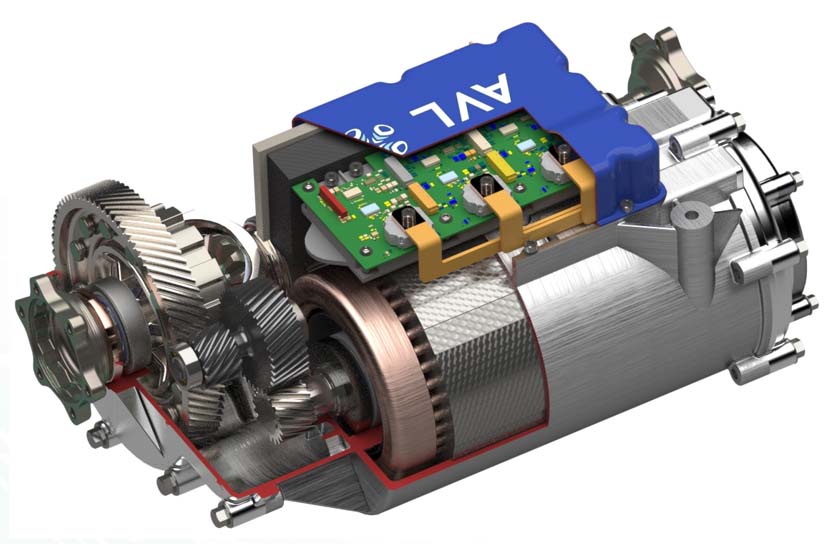

We can connect the electric motor with several types of mechanical.

The material of the motors and the shapes and size of the motors are not unique but the generation of heat does not alter very much depending on.

The heating calculations are.

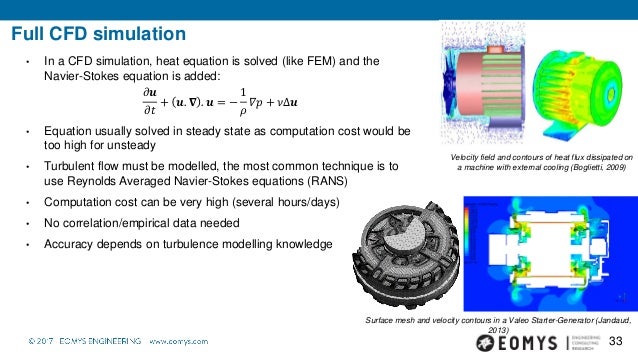

The amount of heat generated inside the motor should be known as accurately as possible.

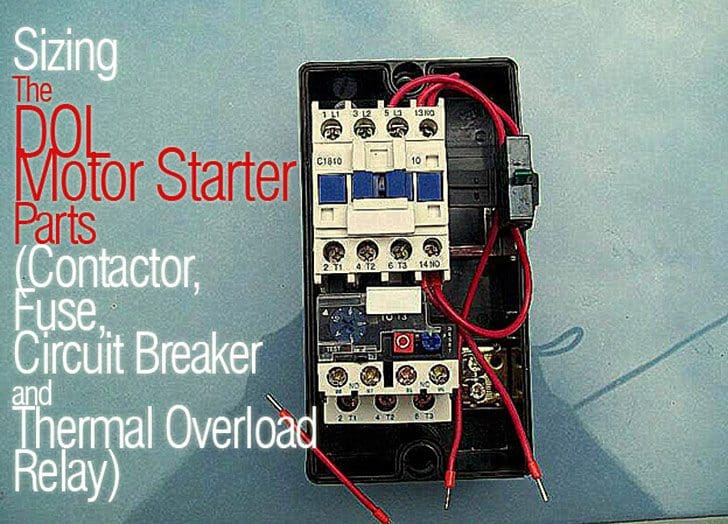

If your electric motor keeps tripping the thermal reset button this table helps find the cause and cure.

This article provides a table of the causes of and cures for an electric motor that overheats or runs too hot.

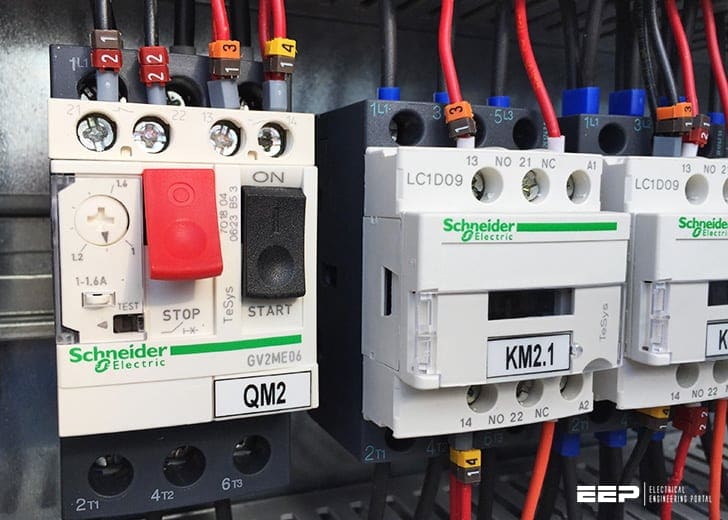

The thermal protector consists of one or more heat sensing elements built into the motor or motor compressor plus an external control device.

Electric motor is the one of common device for rotating equipment and it s useful for smooth operation and make our process more faster and efficiency.

Overheating electric motor diagnosis and repair.

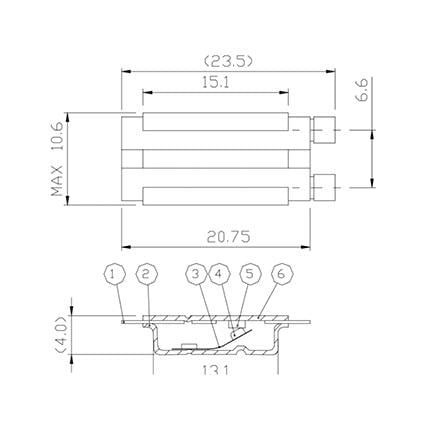

The geometry of an electric motor cooling is too complex to predict accurately the heat flow and temperature distribution.

That s why thermal modeling of motor is necessary.

But we must remember we should sizing the motor capacity properly and must suitable with load system and application for our process.

A portion of the conductors of armature winding are embedded in slots and some portion is outside the iron material as overhang.

Electric motor cooling and heating.

This safety feature halts the temperature climb before it can burn up the motor.

We know that when an electrical motor and drive operates there is a generation of heat inside the motor.

Settings the temperature of the stator is normalized into a unit of percent thermal capacity.

When the stator is cold 40 c the motor has 100 thermal capacity available and 0 thermal capacity used.

When the stator temperature is at the insulation s limiting temperature the motor has 0 thermal.