Forklift pre operational inspection checklist model.

Electric forklift pre operation inspection checklist.

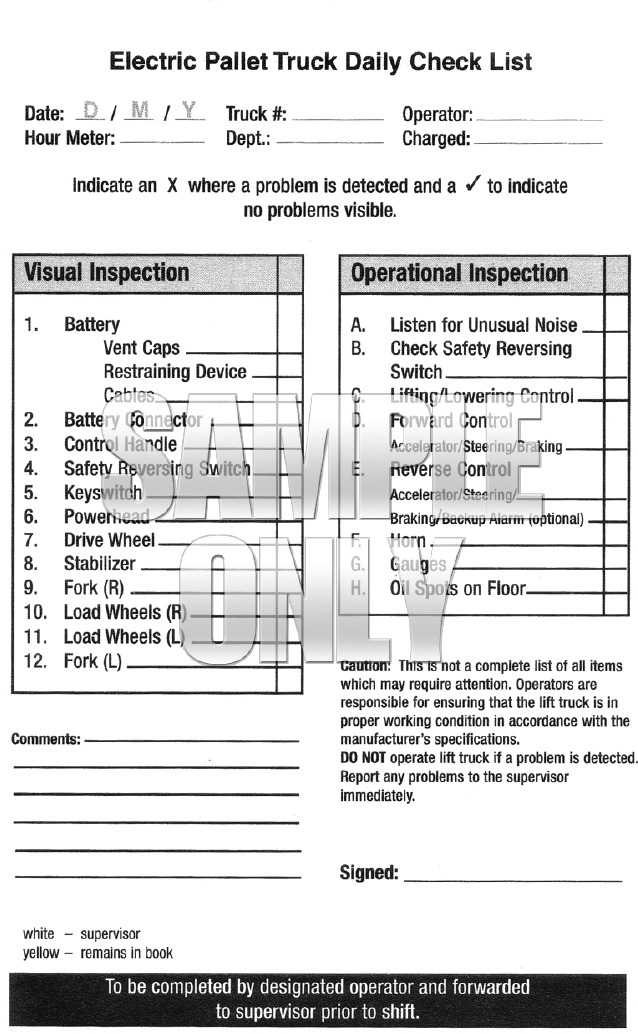

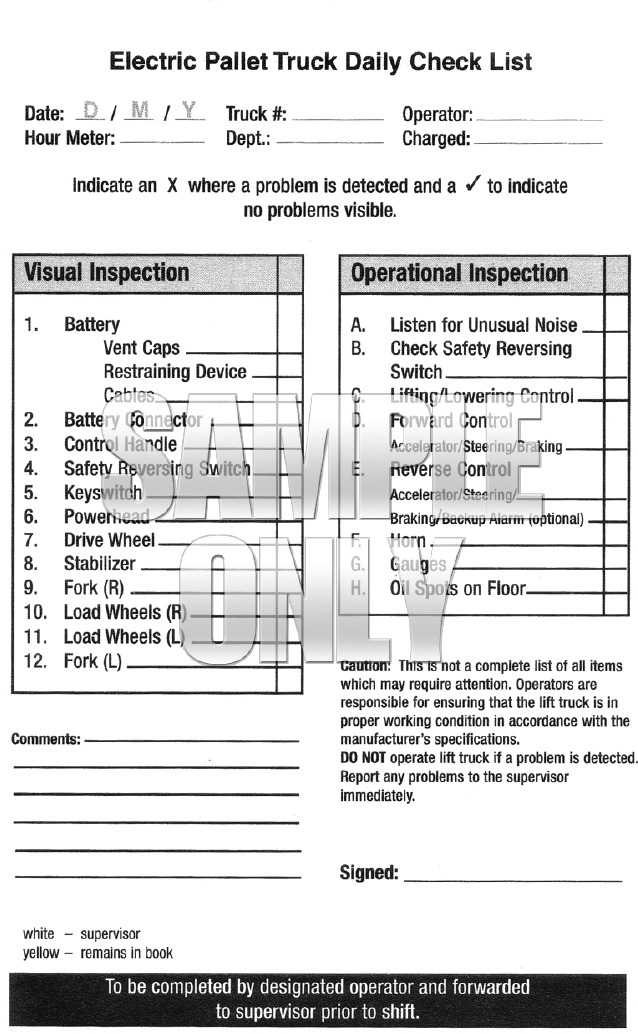

Check ok if the items are in good condition operation or check.

Depicted below are the major types of industrial trucks and some of the most common variations.

Operator 1 operator 2 operator 3 operator 4 operator 5 operator name hour meter reading date month day year operator s signature certified forklift operator.

Pre operation inspections help not only increase the longevity of your electric forklift but also help decrease accidents due to component failure while operating it.

Operator checking the seat belt as part of the pre operation inspection.

Daily pre shift inspection of powered industrial trucks is required by osha standards.

Pre shift class ii order picker forklift inspection checklist class ii forklifts are electric motor narrow aisle trucks or order pickers used for narrow aisle operation.

Electric forklift inspection checklist for the purpose of d aily pre shift inspection of pit powered industrial trucks as required by osha standards 29 cfr 1910 178.

Operator inspecting the load backrest as part of the pre operation inspection.

Operator ensuring that the operator manual is on board the forklift and legible.

Internal combustion cushion and internal combustion pneumatic forklifts pre operation checklist.

Operator ensuring that warning decals are in place and legible.

2 part ncr pre shift inspection log book provides a pit checklist form as osha compliance documentation in pre operation safety and mechanical inspections for electric powered industrial trucks forklift.

Pre operation inspections help to increase the longevity of your forklift and decrease accidents due to component failure.

If you operate an electric ita class i forklift inspect the following daily.

A forklift daily checklist is used prior to the daily operation of a forklift to ensure that it is in good working condition.

Complete this form before each use.

The drawings of the trucks depicted below are intended to represent the typical configuration of trucks for each type.

Here are a few items worth checking on your internal combustion cushion and pneumatic forklifts.

Before beginning be sure the forklift is parked on a level surface the parking brake is applied.

This is not only a good idea to maintain compliance with osha it is a best practice for any forklift fleet.

Check each item prior to the day s initial use of the forklift.

Forklift pre shift inspection guides and checklist download as required by osha every forklift must be inspected before operation.

There is a unique safety inspection procedure that needs to be followed.

This forklift daily inspection checklist is divided into two parts.

1 before starting the engine and 2 after starting the engine.